FULL-SCENE DIGITAL PRINTING PASTE SOLUTION

Focusontheresearchanddevelopment andproductionofhigh-performance printingpastes

RUIEIN

ABOUT RUIEN

As an innovation leader in the field of digital printing,Zhejiang Ruien Chemical Co., Ltd.has beendeeplyengaged intheindustryformorethantenyears,focusingontheresearchand developmentandproductionofhigh-performanceprintingpaste.Wewithgreen,intelligent,customized”asthecore,withcoverageactivity,dispersion,acid,coatingfourprocess dryprintingdigitalprintingpastescheme,andactive,scatteredwetprintingdigitalprintingpastescheme,helpcustomerstoachievehighquality,lowcost,sustainableprinting production,bringyou thewhole scene digital printingpasteproducts new experience.

Contents

Active digital printing paste scheme

Activewet-printing scheme. .03-04

SpecialProcessSolutionforActiveWetPrinting.. .05-06

Activedryprinting scheme. .07-08

Specialprocessschemeforactivedryprinting. ..9-10

Distributed digital printing and paste material scheme

Dispersed andwetprintingscheme. .11-12

Special process schemefordispersed wet printing...13-14

Decentralizeddryprintingscheme. ..15-16

Acidic digital printing paste scheme

Swimwearscheme.. ..17-18

Networklayoutscheme. ..17-18

Nis spinning scheme. ..17-18

Coating digital printing processing solution scheme

Cotton and polyester cotton mixing scheme. .19-20

polyesterprotocol.. ..19-20

Cowboyscheme.. ..19-20

Nylon protocol. .19-20

The prison fastness improvement scheme. ..19-20

ACTIVE WET PRINTING SCHEME

Core advantages

Environmentalprotectionandsafety

AdoptnoAPECOformula,strictlyfollowtheinternationalenvironmentalstandards.

Precise adaptation

Theexclusiveformulaisprovidedaccordingtothenozzlemodel (Kyocera,samba,etc.)and thefabriccharacteristics(cotton,humancotton,etc.).

Excellent presentation

High color saturation, sharp edges, soft skin after the fabric.

Process

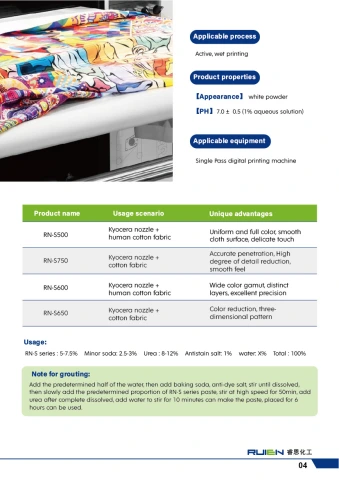

Applicableprocess

Active, wet printing

Product properties

【Appearance】 whitepowder

【PH】 7.0±\:0.5 (1% aqueous solution)

Applicableequipment

SinglePass digital printing machine

| Productname | Usage scenario | Unique advantages |

| RN-S500 | Kyoceranozzle+ humancottonfabric | Uniformandfullcolor,smooth clothsurface,delicatetouch |

| RN-S750 | Kyoceranozzle+ cottonfabric | Accuratepenetration,High degreeofdetailreduction, smoothfeel |

| RN-S600 | Kyoceranozzle+ humancottonfabric | Widecolorgamut,distinct layers,excellentprecision |

| RN-S650 | Kyoceranozzle+ cottonfabric | Colorreduction,three- dimensionalpattern |

Usage:

RN-Sseries:5-7.5%Minorsoda:2.5-3%Urea:8-12%Antistain salt:1%water:X%Total:100%

Note for grouting:

Addthepredeterminedhalfofthewater,thenaddbakingsoda,antidyesalt,stiruntildissolved then slowly add the predetermined proportion of RN-S series paste, stir at high speed for50min,add ureaaftercompletedissolved,addwatertostirfor10minutescanmakethepaste,placedfor6 hourscanbeused.

ACTIVEWETPRINTING SPECIALPROCESS SCHEME

Core advantages

Core advantages

Greenproduction:fully through the environmental protection certification,no harmfulsubstancesresidueintheproductionprocess.

Flexiblecustomization

Specially designed formula for complex processes and special visual effects.

Efficient and compatible

Perfectfitfordiverseprocessneeds,stableand outstandingeffect.

Process

Applicableprocess

Active,wetprintingspecialprocess

Productproperties

【Appearance】

RN-S700/400:whitepowder RN-AG +; lightbrownpowder R-20:colorlesstransparentliquid

【PH】 7.0±\:0.5 (1% aqueous solution)

Applicableequipment

SinglePassdigitalprinting machine orsizingmachine

| Productname | Usage scenario | Unique advantages |

| RN-S700 | Highfineoutput | Precisionreductionofthenozzleoriginal resolution,detailshavenoloss |

| RN-S400 | Imitationwaxprint | Brightcolor,consistentdouble-sidedcolor displayandaccuratepermeabilitycontrol |

| RN-AG + | Terrycloth | Penetrateddeeply,andthevillusspace wascoloredevenly |

| SolubilizedR-20 | lowtotalnitrogenemission | Demandtoreduceureadependence colorstability |

Usage:

Paste:5-6%Minorsoda:2.5-3%Urea:8-12%Antistainsalt:1%waterX%Total:100%

Notefor grouting:

Addthepredeterminedhalfofthewater,thenaddbakingsoda,anti-dyesalt,stiruntildissolved thenslowlyadd thepredeterminedproportionofRNseriespaste,stirathighspeedfor50min,after completelydissolved,addureaandsupplementwatertostirfor10minutestomakethepaste, placedfor6hourscanbeused.

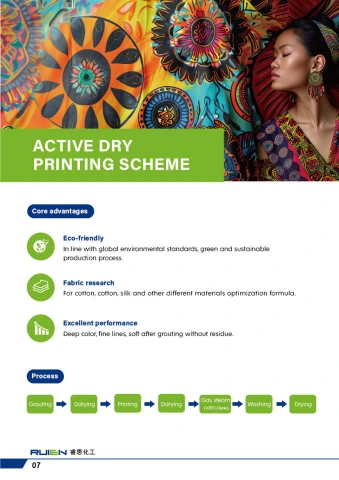

ACTIVE DRY PRINTING SCHEME

Core advantages

Eco-friendly

Inlinewithglobalenvironmentalstandards,greenandsustainable productionprocess.

Fabricresearch

1,cotton,silkand otherdifferentmaterialsoptimiz

Excellentperformance

Deep color, fine lines, soff affer grouting without residue.

Process

Active, dry printing

Applicableprocess

Productproperties

【Appearance】white powder 【PH】 7.0±\:0.5 (1% aqueous solution)

Applicableequipment

Sizing machineor settingmachine

| Productname | Usagescenario | Unique advantages |

| RN-G600 | Dry printing+ cottonandlinenfabric | Colorstability,convenienttopaste stablesystem |

| RN-G500 | Dry printing + humancottonfabric | withdeepcolor,uniformhaircolor easytoclean |

| RN-DS30 | Dry printing+ silkfabric | Fullincolor,clearoutline,no damagetofiber |

| RN-GZ+ | Dry printing + knittingmaterial | Permeabilityisstrong,uniform coloring,easytoremovepaste |

Usage:

「soda:2.5-3%Urea:8-12%Antistain salt:1%water:)

Note for grouting:

Addthepredeterminedproportionofwatertotheslurrybarrel,thenaddbakingsoda,urea,anti-dye salt, stiruntil dissolved, and then slowly add the predetermined proportion of paste,add while stirring. After allfeeding,continue tostir athighspeedforabout40mincanmakepaste,placed for1-2hours canbeused.

ACTIVEDRYPRINTING SPECIAL PROCESS SCHEME

Core advantages

Low-carbpn environmental protection

NoAPEOadded in thewholeprocess,in linewithinternational environmental regulations.

Processinnovation

Developmentforspecial scenessuchasdouble-sidedprintingand round netpulp.

Costreduction andefficiencyimprovement

Optimizetheformula toreducethedosageand simplifytheproductionprocess.

Applicableprocess

Active,dry printing special process

Productproperties

【Appearance】 whitepowder

【PH】 7.0±0.5 (1% aqueous solution)

Applicableequipment

Sizing machine or round net printing machine

| Productname | Usage scenario | Unique advantages |

| RN-G300 | Dryprinting+double- sidedprinting | Colordifferences0.5level,accurate precisioncontrol |

| RN-G200 | Dryprinting+circularpulp | Insteadoftherollingprocess,the groutingefficiencyincreasedby30% |

| RN-L6 | Dryprinting+ultra-low dosagedemand | Dosagewasreducedby75%,and thecomprehensivecostwas significantlyreduced |

Usage:

G300:2.5-3%G200:5-6%L6:0.6-0.7%Minor soda:2.5-3%Urea:8-12%Antistain salt:1%water:X% Total:100%

Note for grouting:

Add thepredeterminedproportionofwatertotheslurrybarrel,thenaddbakingsoda,urea,anti-dye salt, stir until dissolved,and then slowly add thepredetermined proportion of paste, add while stirring. Afferallfeeding,continuetostirathighspeedforabout40mincanmakepaste,placedfor1-2 hourscanbeused.

DISPERSEDAND WET PRINTINGSCHEME

Environmentalprotection certification

Equipment coordination

Quality assurance

ThewholeseriesofOEKO-TEX {18} standard testing.

Suitabletotheneedsof samba,Kyoceranozzleand thickcloth.

Bright color, clear lines,no hard feeling affer grouting

| Productname | Usagescenario | Unique advantages |

| RN-D500 | Sambahead+thickcloth | Highpermeability,darkexpression isprominent |

| RN-D550 | Sambanozzle+thincloth | Thinfabricisnotdye,sharpandclearpattern |

| RN-D600 | Kyocerasprayhead+ thickcloth | Highcolor,goodpenetration,excellentfeel |

| RN-D650 | Kyocerasprayhead+ thincloth | Preciseinkcontrol,reduceinkwaste |

Applicable equipment:

Single Pass digital printing machine

Notefor grouting:

Addapredeterminedproportionofwatertotheslurrybarrel,and then slowlyadd thepredetermined proportion of RN-D seriespaste,and stir while adding.Affer all feeding,continue tohigh-speed mixing forabout50mincanmakeapaste,placedfor48hoursofnatural expansion,andthenhigh-speed mixingfor5mincanbeused.

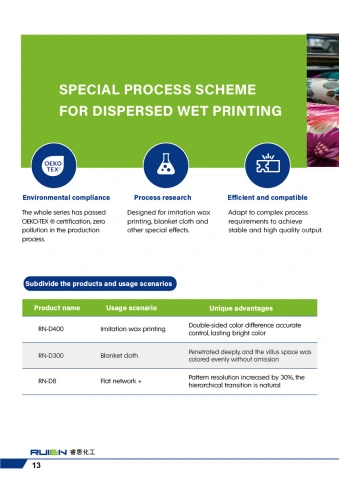

SPECIAL PROCESS SCHEME FOR DISPERSED WET PRINTING

Environmental compliance

Processresearch

Efficient and compatible

The whole serieshaspassed OEKO-TEX {{\scriptsize B}} certification,zero pollution in the production process.

Designedforimitationwax printing,blanketclothand otherspecialeffects.

Adapttocomplexprocess requirementstoachieve stable and highqualityoutput.

| Productname | Usage scenario | Uniqueadvantages |

| RN-D400 | Imitationwaxprinting | Double-sidedcolordifferenceaccurate control,lastingbrightcolor |

| RN-D300 | Blanketcloth | Penetrateddeeply,andthevillusspacewas coloredevenlywithoutomission |

| RN-D8 | Flatnetwork+ | Patternresolutionincreasedby30%,the hierarchicaltransitionisnatural |

Applicableprocess:

Product properties:

Dispersion,wetprintingspecialprocess

【Appearance】

D400:beigepowder

D300:light brown liquid

D8:whitepowder

【PH】 7.0±0.5 (1% aqueous solution)

Applicable equipment:

SinglePass digital printing machineorsizingmachine

Note for grouting:

Addthepredeterminedproportionofwatertotheslurrybucket,andthenslowlyaddthe predeterminedproportionofpaste,and addwhilestirring.Afferallfeeding,continuetostirathigh speedforabout50mincanmakeapaste,placedfor1-2hourscanbeused.

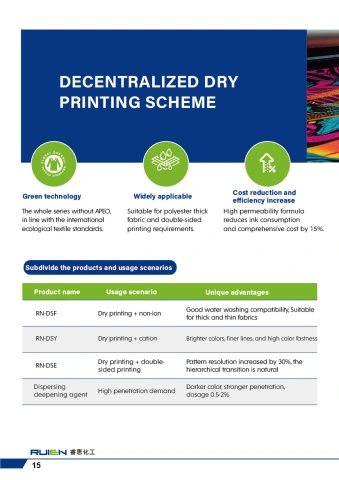

DECENTRALIZED DRY PRINTINGSCHEME

Green technology

Widelyapplicable

Costreduction and efficiencyincrease

ThewholeserieswithoutAPEO, inlinewiththeinternational ecological textilestandards.

Suitableforpolyesterthick fabricanddouble-sided printing requirements.

Highpermeability formula reduces ink consumption and comprehensive cost by 75%.

| Productname | Usage scenario | Unique advantages |

| RN-DSF | Dryprinting+non-ion | GoodwaterwashingcompatibilitySuitable forthickandthinfabrics |

| RN-DSY | Dryprinting+cation | Brightercolors,finerlines,andhighcolorfastness |

| RN-DSE | Dryprinting+double sidedprinting | Patternresolutionincreasedby30%,the hierarchicaltransitionisnatural |

| Dispersing deepeningagent | Highpenetrationdemand | Darkercolor,strongerpenetration, dosage0.5-2% |

Product properties:

【PH】 7.0±0.5 (1% aqueous solution)

【Appearance】

DSFandDSE:whitepowder

DSY:lightyellowTransparentliquid

Dispersing deepening agent:colorless transparent liquid

Applicable equipment:

Decentralized,dryprinting

Applicableprocess:

Sizing machine or setting machine

Note for grouting:

Add apredeterminedproportionofwatertotheslurrybarrel,and thenslowlyadd thepredetermined proportion of RN-Ds series, while adding while stirring.After all feeding, continue to stir for about 20min,andleaveitforabout1hourcanbeused.

ACIDICDIGITALPRINTING PASTESCHEME

Environmentalprotection

ThewholeseriesexcludingAPEO,inlinewithinternationalenvironmental protectionstandards.

Customization

Tailored to differentfabrics(swimsuit cloth,meshcloth,Nylontaffeta).

Highperformance

Darkcolor,clearouline,sofffeel afterunsizing.

Process

| Productname | Usagescenario | Unique advantages |

| RN-A100 | Dry printing + swimsuitcloth | Withhighcolorquantity,brightcolor suitableforelasticfabric |

| RN-A200 | Dryprinting+meshcloth | Goodermeabilitydistinctpattems,suitable forhollowfabric |

| RN-A300 | Dry printing + Nylontaffeta | Clearoutline,stronganti-diffusioneffect suitableforlightandlightfabrics |

| Productproperties: | 【Appearance】lightyellowpowder | 【PH】7.0±0.5(1%aqueoussolution) |

| Applicableprocess: | Acid, dry printing | |

| Applicableequipment: | Sizingmachineorsettingmachine | |

| Usage:RN-Aseries:4-5% | Ammoniumsulfate:1-2% | Urea:1-2% water:X% Total:100% |

Note for grouting:

Addapredeterminedproportionofwatertotheslurrybarrel,andthenslowlyaddthepredetermined proportionofammoniumsulfate,rea,RN-Aseries,andstirwhileadding.Afferallfeeding,continueo stirforabout40mincanmakepaste,placedforabout1-2hourscanbeused.

COATINGDIGITALPRINTINGPROCESSINGSOLUTION SCHEME

Environmentalprotection

Thewholeseriesexcluding APEO,inlinewithinternational environmentalprotection standards.

Fabric specialty

For cotton, polyester, denim,nylonand other differentiatedneedsdesign.

High performance

Dark color,good colorf astness,softfeel.

Product properties:

【Appearance】colorless and transparent liquid 【PH】 6.0±0.5 1% aqueoussolution) Coating, dry printing

Applicable process:

| Productname | Usage scenario | Uniqueadvantages |

| RN-TGM | Dryprinting+cotton, polyestercottonblended | Colordepth,dryandwetfrictionfastnessis good,soffandnothardening |

| RN-TGD | Dryprinting+polyester | Hightemperaturesettingdoesnotyellow colorsaturationincreasedby20% |

| RN-TGN | Dryprinting+denim | Fullcolor,retainthedenimruggedstyle |

| RN-TGL | Dry printing +nylon | Colorfastnessnodamagetothefiberstrength |

| RN-FIX1 | Dry printing + fastnessincrease | Jointbathwithsoffenersignificantlyimprove frictionfastness |

Note for grouting:

Addapredeterminedproportionofwatertotheslurrybarrel,andthenslowlyaddthepredetermined proportionoftreatmentliquid,andstirwhileadding.Afferallfeeding,continuetostirathighspeed forabout20min,anditcanbeusedfor1hour.

CUSTOMIZEDPRODUCTSANDOPTIMIZEDSERVICES

Basedonthecustomer'sexistingprocessformula,ourprofessionalscanprovidedetailedand completeexperimentaldata,soastoprovidecustomerswithcustomizedproductsandprocesses thatareclosertotheirneeds,andoptimizethecustomer'sslurryqualityandcosttothegreatestextent.

DAILYAPPLICATIONTECHNOLOGYSERVICES

Ourapplicationtechnologyteamwillmaintaindailycommunicationwithcustomerstoensurethe correctuseoftheproducts.

ANALYSIS,EVALUATIONANDTESTING

The company isequippedwithvarioushigh-precision instruments,which canprovidestrong support forcustomers'formulaoptimizationandproblemmatching.

Through the"green, intelligent and customized" product design, Ruien Chemical provides accurate solutions for different processes, fabrics and special needs, taking into account high-quality output and cost-effectiveness,andhelpscustomerstoachieve efficient and environmentally friendly digital printing production.

Green·Intelligent·Customized

ZHEJIANGRUIENCHENMICALCO.,LTD

Add:Shaoxing.Zhejiang

Tel:0575-88151314

Mobile:15005759556

Email:ruienhg@163.com

該頁無縮略圖

該頁無縮略圖